When it comes to cable design and testing, static flexibility testing is a crucial step. This type of testing is applicable to various cable types, particularly welding electrode cables and hoisting cables, with the aim of ensuring that the cable does not deform under static conditions. This article will delve into the process, standards, and significance of static flexibility testing.

Purpose and Standards of Testing

The primary purpose of static flexibility testing is to validate the flexibility and resistance to deformation of cables under specific conditions. These tests are conducted in accordance with the standards set by the International Electrotechnical Commission (IEC), specifically complying with IEC 60245-1 clause 5.6.3.2 and IEC 60245-2 clause 3.2. These standards ensure the consistency and comparability of the testing, allowing different cable types to undergo the same testing process for effective comparison and evaluation.

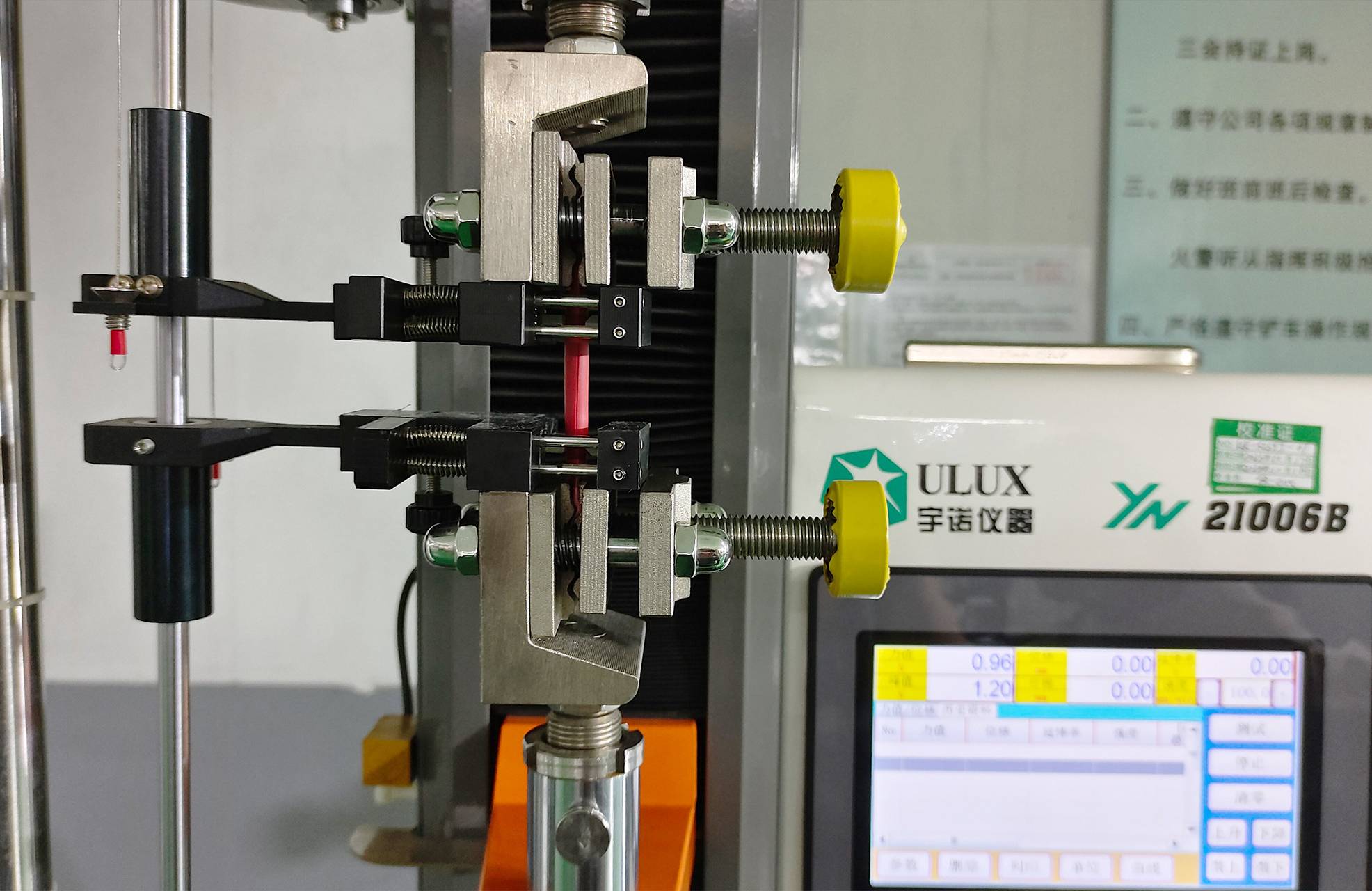

Testing Equipment and Samples

In static flexibility testing, a specific set of testing equipment is typically used. These devices include two fixtures, usually labeled as A and B. Fixture A is fixed, while fixture B can be moved horizontally. During testing, one end of the cable sample is clamped in fixture A, and the other end is secured in the movable fixture B, with a distance of approximately 0.20 meters between them. The cable takes on a specific U-shaped bend, tangent to two plumb lines, and this shape is a crucial part of the testing.

Testing Procedure

Once the testing begins, the movable fixture B moves away from the fixed fixture A until the cable takes on a U-shaped configuration. This process simulates the bending of the cable under specific conditions. The testing is performed twice, and after the first test, the cable is rotated 180° within the fixtures for the second test. These two tests aim to ensure the cable's flexibility in different directions.

Test Results and Significance

After testing is completed, the data from the two test runs are measured, and the average of these measurements is calculated. This average is used to evaluate the cable's static flexibility. To pass the test, the average value must not exceed specific values stipulated in the relevant standards, which are detailed in those standards. This is a crucial step in ensuring the quality and performance of the cable.

Static flexibility testing is vital for cable design and manufacturing. It ensures the reliability of cables in specific applications, especially those that involve bending and twisting. By following the standardized testing process, manufacturers can ensure that their products meet industry standards, providing higher quality and reliability while reducing potential risks. This makes static flexibility testing an indispensable part of the cable industry.